XBH 60cm DTF printer with powder vibration oven for apparel and footwear printing.

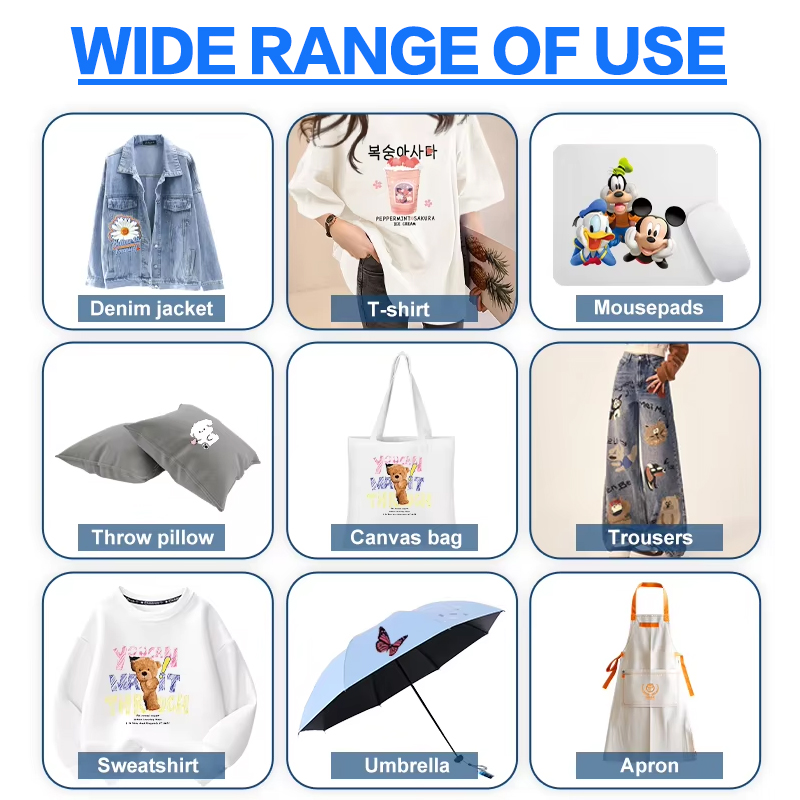

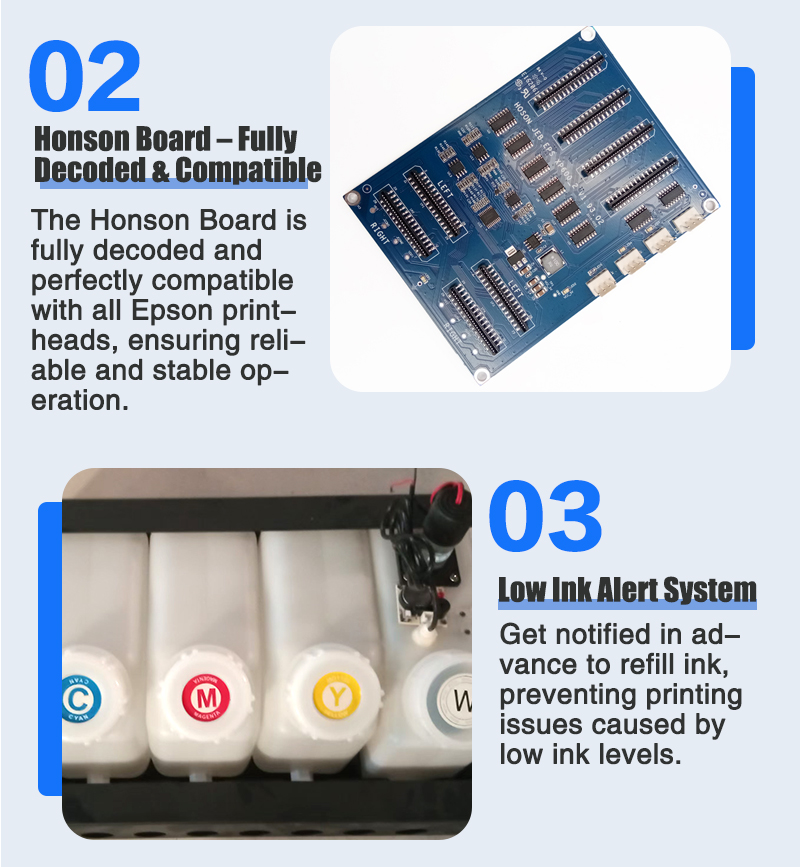

Highly adaptable: Compatible with the Epson ecosystem, equipped with i3200/4720 industrial-grade printheads, ensuring accurate color reproduction and stable output. 60cm wide-format printing meets the needs of mass production and personalized customization, and is compatible with various PET transfer films. Utilizes DTF textile pigment inks, offering strong adhesion, washability, and long-lasting color, suitable for printing on various textiles such as T-shirts and canvas bags.

Against the backdrop of accelerating global trends in garment customization and small-batch production, XBH has launched a 60cm DTF printer + powder shaker and dryer combo. This one-stop device integrates high-precision printing, automatic powder shaker, and constant-temperature drying. With its technological innovation and localized manufacturing advantages, it brings a comprehensive upgrade from efficiency to quality to the garment printing industry, helping small and medium-sized businesses and entrepreneurs seize the opportunity in the wave of flexible production.

The XBH 60cm DTF printer is powered by an Epson i3200/4720 industrial-grade printhead, paired with dedicated DTF textile pigment ink. This allows the printer to achieve high-precision output of 1440dpi, while also breaking through in color reproduction and weather resistance. The ink particles are fine and have strong penetration, producing vibrant and saturated colors on various fabrics such as cotton, polyester, and blends. Even after multiple washes, the prints remain fade-free and crack-free, fully meeting the quality requirements of branded apparel. The 60cm wide print size supports both large-format single-sheet printing and continuous multi-station printing for mass production, perfectly balancing the needs of personalized customization and large-scale production.

Fully automatic printing: The equipment supports continuous paper feeding and automatic deviation correction. With USB 3.0 high-speed data transmission, it only takes a few minutes to send the file to the pattern output. Intelligent powder shaking and drying integration: The matching powder shaking machine adopts electrostatic adsorption technology, which can automatically and evenly spread powder and recover excess powder, reducing material waste. The subsequent constant temperature drying system ensures that the hot melt powder is completely melted through precise temperature control, so that the pattern is firmly bonded to the fabric. The whole process does not require manual supervision. Wide system compatibility: It supports all Windows 7/8/10 operating systems and is compatible with mainstream design software. Designers can directly output creative files to the equipment, which greatly shortens the delivery cycle from design to finished product.

The XBH 60cm DTF Roll Printer not only lowers the industry entry barrier, but also enables independent designers, trendy online stores, e-commerce sellers and other small and medium-sized practitioners to easily possess professional-grade printing capabilities, truly realizing a production model of "small batch, fast turnaround, and high quality。