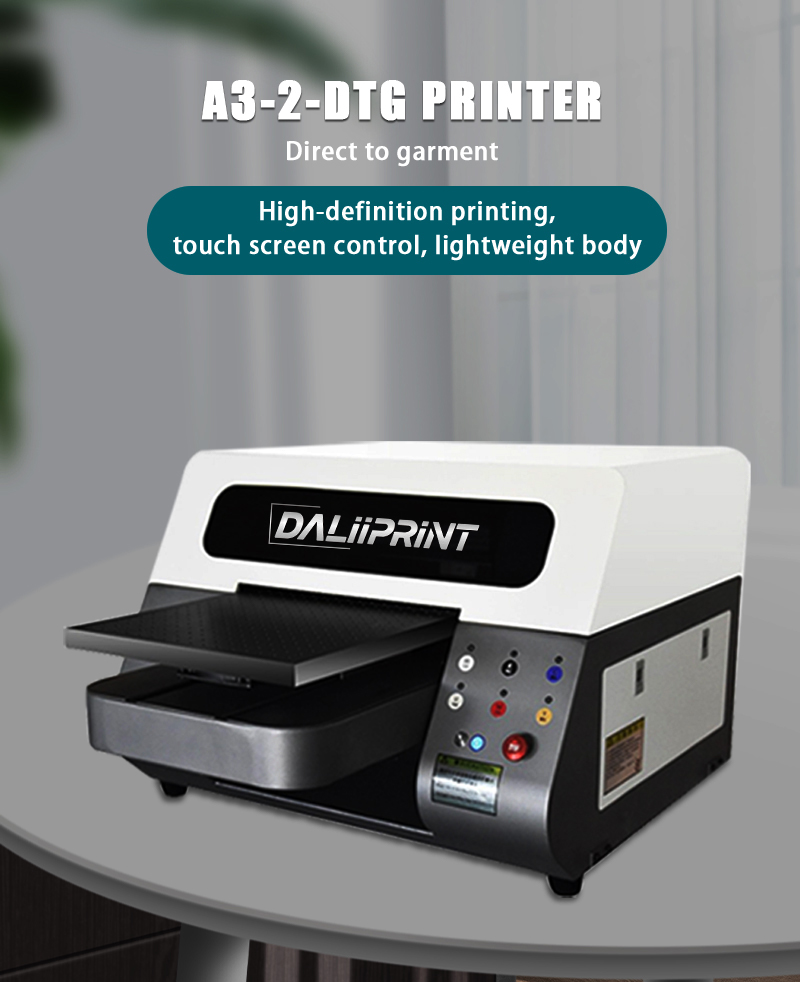

F1080 Dtg Printer Machine

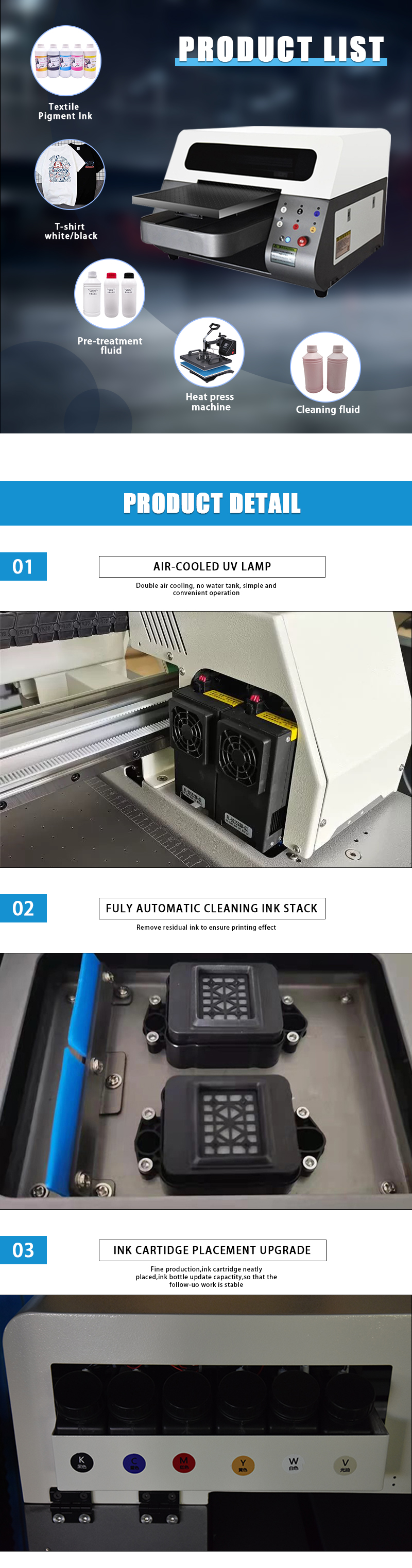

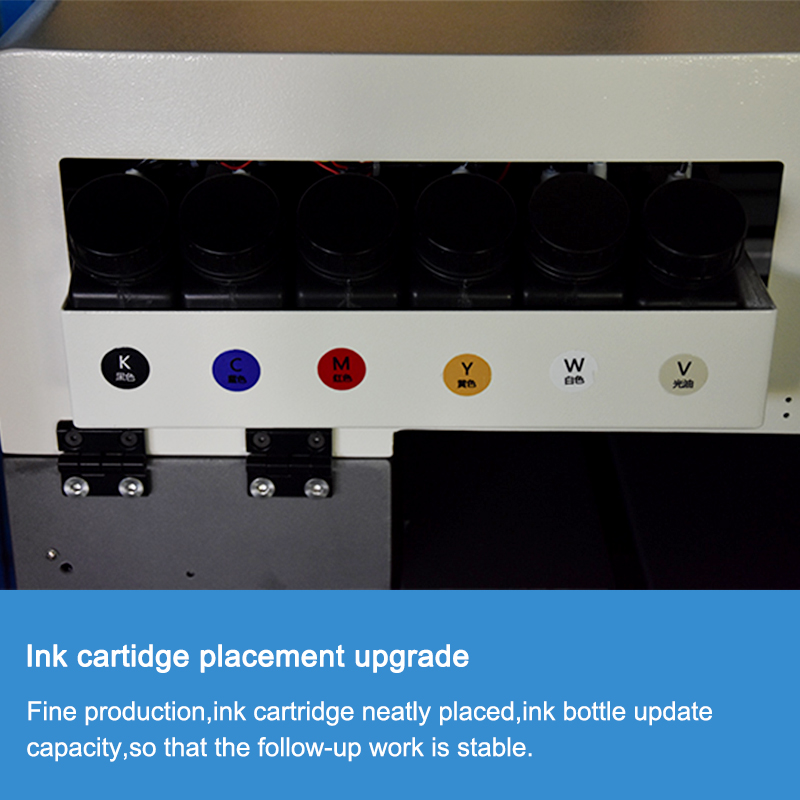

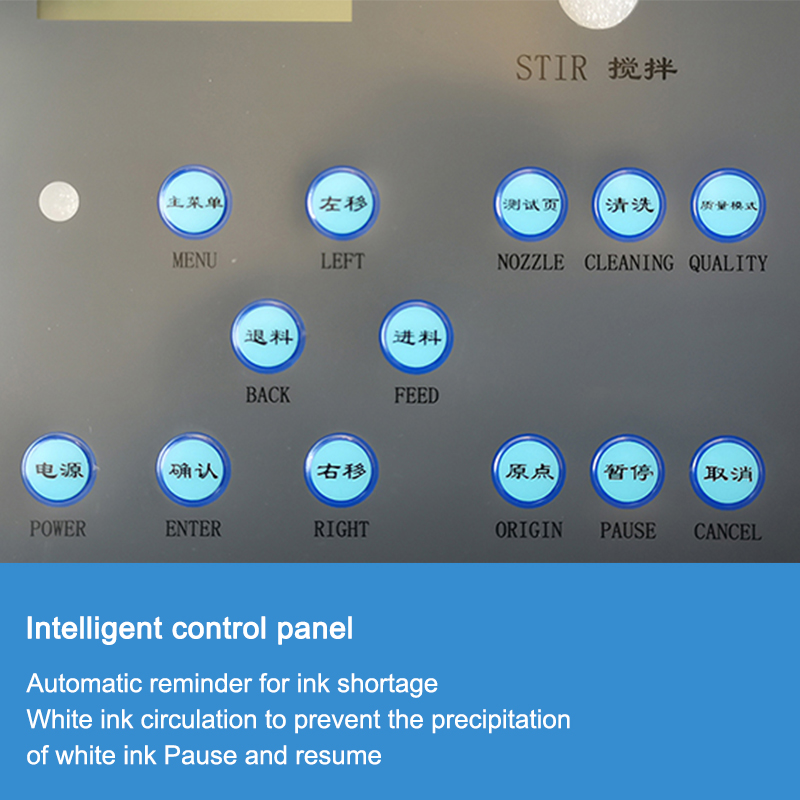

Because of the continuous ink supply, the printing speed is faster, and the white ink function is added.

The printing effect of white ink does not fade, scratch-resistant, waterproof, and environmentally friendly. The printing effect is clear and increases the three-dimensional and heavy feeling of the picture.

F1080 Dtg Printer Machine

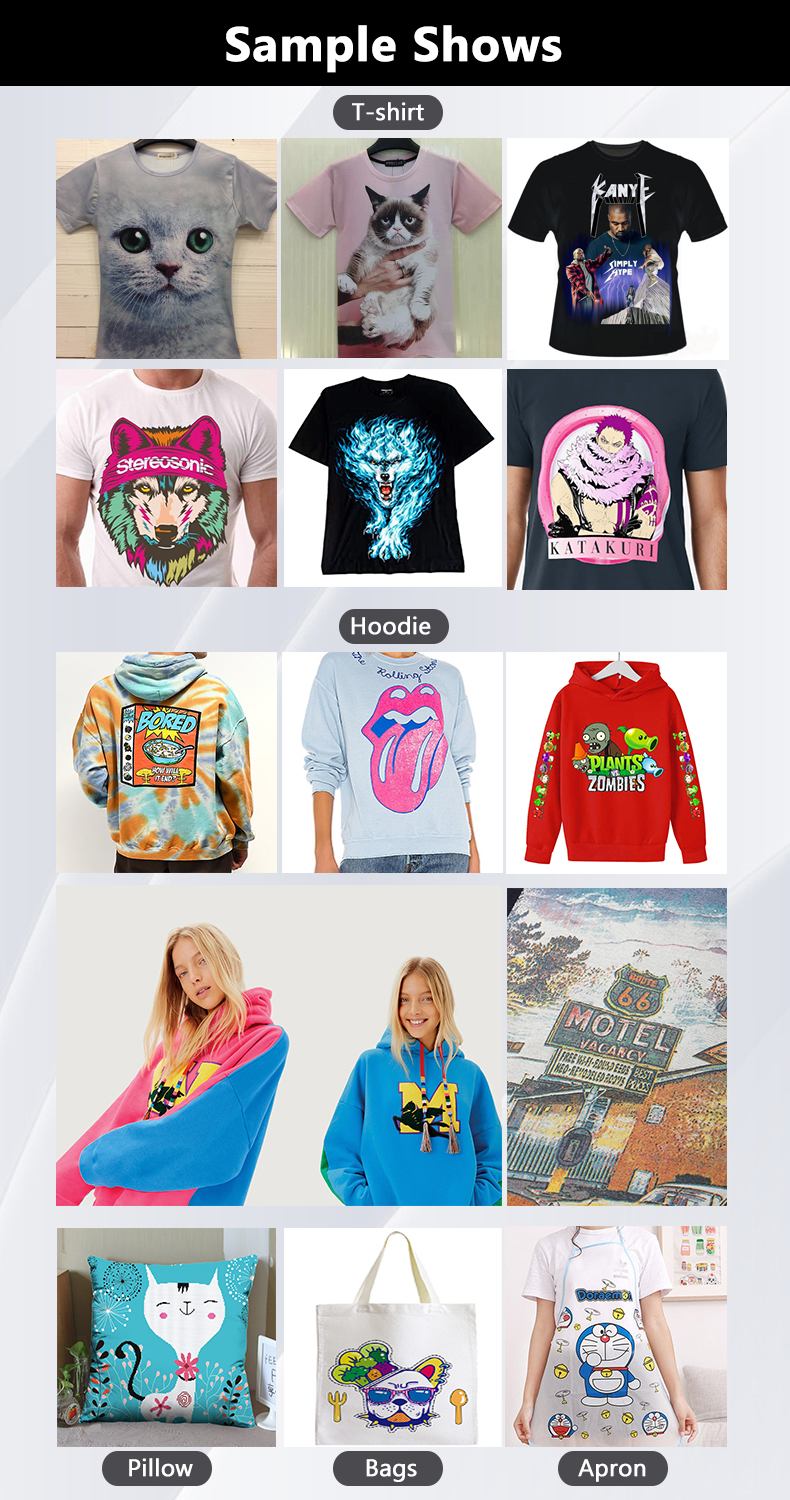

It’s so easy to get carried away by the fact that you can buy a DTG printer, start a website, and start selling printed T-shirts, and life will be so good. Well, it’s not always that simple. DTG printers should work every day if that’s possible and you need to print a few t-shirts per day for it to work.

Certainly, there is a lot of competition in this industry and sometimes it is possible to end the day without printing a single shirt. A DTG printer is full of color, quick to respond, and you need to know how it fits in with your business model.