Revolutionizing Printing: Unveiling the Power and Precision of DTF Printers

Revolutionizing Printing: Unveiling the Power and Precision of DTF Printers

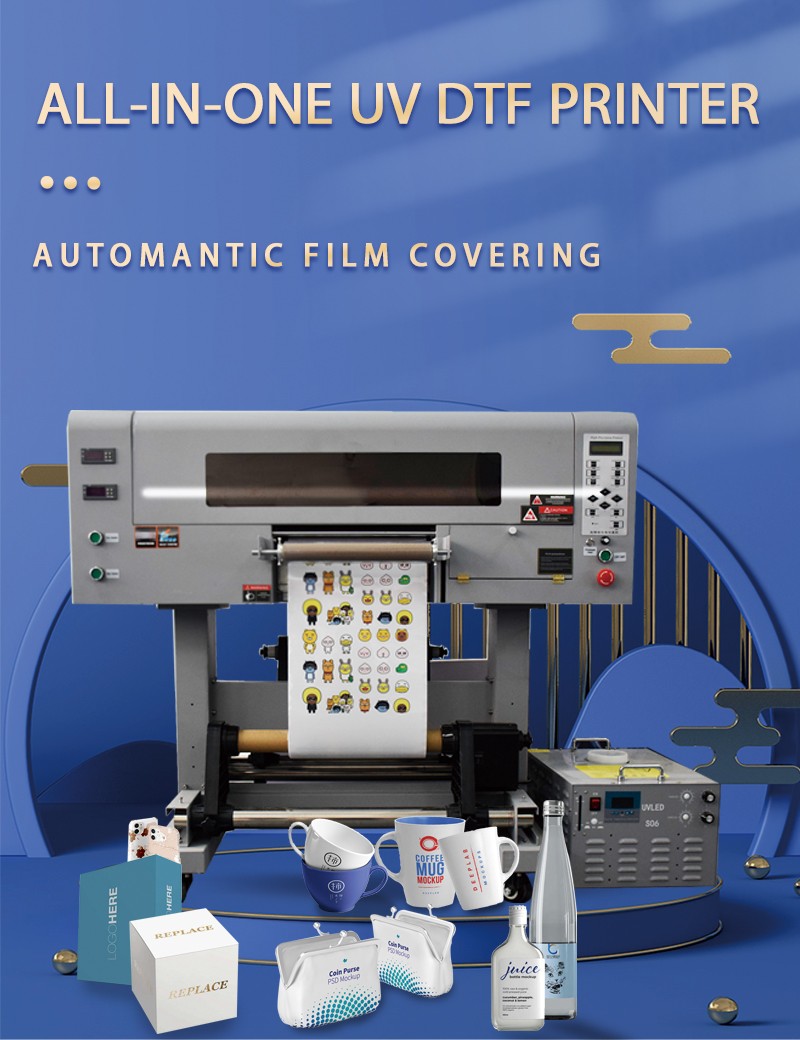

In the rapidly evolving world of printing technology, DTF (Direct to Film) printers have emerged as versatile tools that offer enhanced capabilities for high-quality printing on various materials. Let's delve into the details of DTF printers, including their key parameters, features, and usage guidelines.

Parameters Information:

Resolution: DTF printers typically offer a high-resolution printing capability, ranging from 720 DPI to 1440 DPI, ensuring crisp and detailed output.

Printing Width: The printing width of DTF printers varies, with common sizes including 60 inches, 74 inches, and 104 inches, catering to different printing needs.

Ink Compatibility: DTF printers support a wide range of inks, including eco-solvent, sublimation, and pigment inks, providing flexibility for diverse printing applications.

Heating System: Equipped with advanced heating systems, DTF printers ensure proper ink curing and adhesion for durable prints.

Software Compatibility: DTF printers are often compatible with popular design software such as Adobe Illustrator and CorelDRAW, enabling seamless integration into existing workflows.

Features Overview:

DTF Film Feeding Mechanism: DTF printers utilize a specialized film feeding system that ensures smooth and precise media handling during the printing process.

White Ink Printing: Many DTF printers offer the capability to print white ink, allowing for vibrant and opaque prints on colored or dark substrates.

User-Friendly Interface: With intuitive controls and user-friendly interfaces, DTF printers make printing operations efficient and accessible for users of varying expertise levels.

High-Speed Printing: DTF printers are known for their fast printing speeds, enabling quick turnaround times for projects without compromising on print quality.

Usage Guidelines:

Design Preparation: Create or import the desired design into the printer software, ensuring it is compatible with the DTF printing format.

Film Placement: Load the DTF film onto the printer platen, securing it properly for accurate printing.

Ink Selection: Choose the appropriate ink type based on the material being printed on and adjust settings accordingly.

Printing Process: Initiate the printing process, monitoring the print quality and adjusting settings as needed to achieve the desired results.

Post-Printing: Allow the print to dry and cure properly before handling or transferring it onto the desired substrate.

With their advanced features and user-friendly design, DTF printers are revolutionizing the printing industry by offering efficient, high-quality printing solutions for a wide range of applications. Stay tuned for further developments and innovations in DTF printing technology as it continues to shape the future of printing and customization.