DTG Printers: A Comprehensive Overview of Features and Operational Procedures

DTG Printers: A Comprehensive Overview of Features and Operational Procedures

DTG (Direct-to-Garment) printers have emerged as a game-changer in the printing industry, offering unmatched versatility and efficiency. Let's delve into the various parameters and operational steps of these innovative printing machines.

Parameters of DTG Printers:

1.Printing Technology: DTG printers employ advanced inkjet technology to directly print designs onto garments, ensuring high-quality and durable prints.

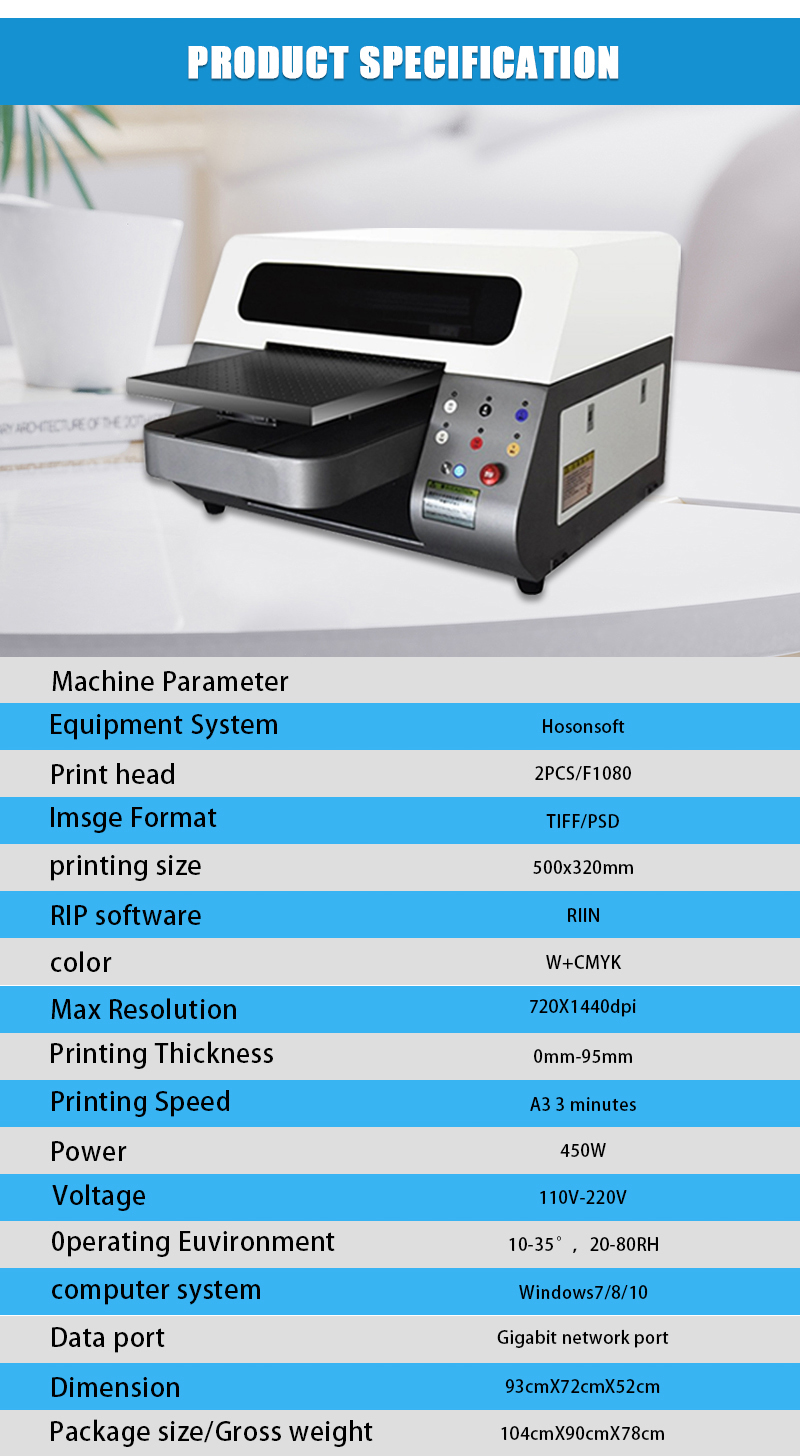

2.Printing Size: These printers come in different sizes, catering to a range of garment dimensions, from small items like t-shirts to larger apparel pieces.

3.Resolution: With superior print resolutions, DTG printers deliver sharp and vibrant prints, capturing intricate details and color gradients with precision.

4.Ink System: DTG printers utilize specialized textile inks that bond well with fabrics, resulting in long-lasting and wash-resistant prints without compromising softness.

5.Garment Compatibility: DTG printers are designed to print on various types of fabrics, including cotton, polyester blends, and more, offering flexibility for diverse garment choices.

Operational Steps of DTG Printers:

1.Preparing the Garment: Ensure the garment is flat and positioned correctly on the printer platen, securing it in place for precise printing.

2.Design Setup: Prepare the digital design file to be printed on the garment, adjusting colors, size, and placement as needed using the printer software.

3.Pretreatment: Apply a pre-treatment solution to the fabric before printing to enhance ink adhesion and ensure vibrant and durable prints on the garment.

4.Printing Process: Initiate the printing process through the printer's control panel or software interface, allowing the machine to apply the design onto the garment with precision.

5.Curing: After printing, heat press or cure the printed garment to set the ink and ensure lasting durability, following the manufacturer's recommendations for the specific ink used.

DTG printers have revolutionized the custom apparel industry, enabling businesses to create personalized and on-demand clothing with ease. With their versatile parameters and user-friendly operational steps, DTG printers continue to drive innovation and creativity in the world of garment decoration, offering endless possibilities for custom designs and unique fashion statements.